CETOL 6σ Accelerates Schedule by Over 250%

About The Project

This case study involves a product made by FN Manufacturing, part of the Belgium-based Herstal Group. FN Manufacturing is a precision manufacturing company that supplies small arms for military applications. The contract bid required 230 unique tolerance studies to be conducted. These analyses included 1D, 2D, and 3D tolerance models that included worst case and statistical results. Reports needed to be self-explanatory. The time frame to complete the project was 7 months. Prior to employing CETOL 6σ, tolerance analysis was done manually.

Contract Requirements

- 230 required tolerance studies

- 1D, 2D, and 3D tolerance models

- Worst case and statistical results needed

- Reports must be self-explanatory

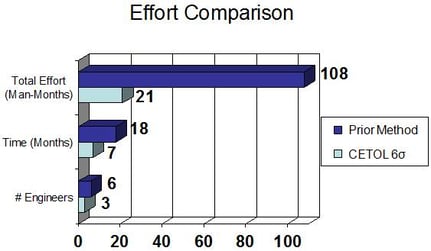

In order to validate CETOL 6σ for use in the FN Manufacturing product development and concurrent engineering process and meet the company’s ROI (return on investment) requirement, the software had to meet several criteria. For the ROI, the key metric was productivity. CETOL 6σ was compared to a previous, very similar contract bid effort. After taking just basic training and minimal coaching from Sigmetrix, FN Manufacturing engineers effectively conducted the required analyses. The results from the productivity comparison showed a 250% reduction in schedule time and over a 500% reduction in total effort.

About FN Manufacturing

FN Manufacturing is a precision manufacturing facility with a rich military heritage as a small arms supplier to the U.S. Military and ninety other countries around the world. They offer services to aerospace, firearms and other industries requiring exacting tolerances and tight quality control. Capable of taking a design from concept through distribution, the quality and reliability expected of military applications carries over into everything they build.