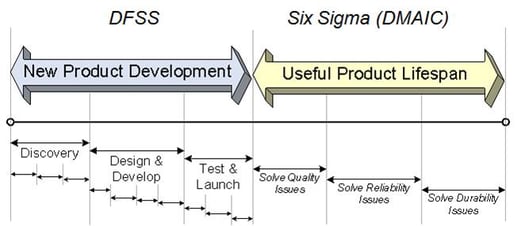

DFSS, or Design for Six Sigma, is a customer-focused product development attitude and methodology that effectively translates the Voice of The Customer (VOC) into a robust design. DFSS is primarily used for the development of manufactured products, but can also be used for software development, infrastructure development, and process design. One of the primary objectives is to create products and services that consistently meet the critical requirements as defined by the customer. To support this objective, DFSS is focused on the concept and design of new products or processes, even if they are incremental improvements to existing designs. This is in contrast with Six Sigma (DMAIC: Define, Measure, Analyze, Improve, Control) which focuses primarily on improving existing products or processes.

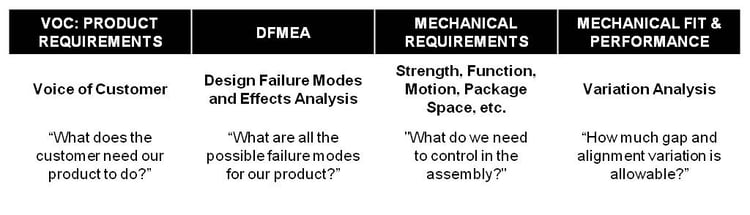

While there are many aspects to DFSS, understanding failure modes is critical to the life of the product. During the DFSS phase, the project leader and ultimately design engineer have a significant responsibility to produce a robust product. To do so, the voice of the customer must be documented and clearly defined as product requirements. DFMEA, or Design Failure Modes and Effects Analysis, should then be conducted to understand, “What can go wrong?” From this exercise, a set of engineering requirements are defined that consider product needs in terms of the mechanical, electrical, software, optical, chemical, etc. requirements.

At this point, it becomes the challenge of the design and engineering community to not only design a robust product, but to prove it. The acronyms DMADV (Design, Measure, Analyze, Design, Verify) and IDOV (Identify, Design, Optimize, Verify), commonly associated with DFSS, clearly call for “proof” at the “Verify” stage. Verification using a virtual model can result in a significant competitive advantage in the product development process. Companies that use software tools like FEA, CFD, and variation analysis software have proven success in reducing time-to-market, reducing costs in scrap, rework, prototypes, field failures, and warranty issues. This virtual product development approach enables companies to pursue multiple design concepts simultaneously as well.

Verification of product performance and ease-of-assembly is easily achieved using software like CETOL 6σ.