Tolerance Stackup Justification

Every product manufactured today is subject to variation. From the peaks and valleys of integrated circuits in the microscopic regime, to the buttons on the cell phone in your pocket, to the structures of bridges and the space shuttle in the macroscopic regime, no product or part is immune from variation. Understanding this variation and quantifying its effect on the form, fit and function of parts and assemblies is a crucial part of the mechanical design process.

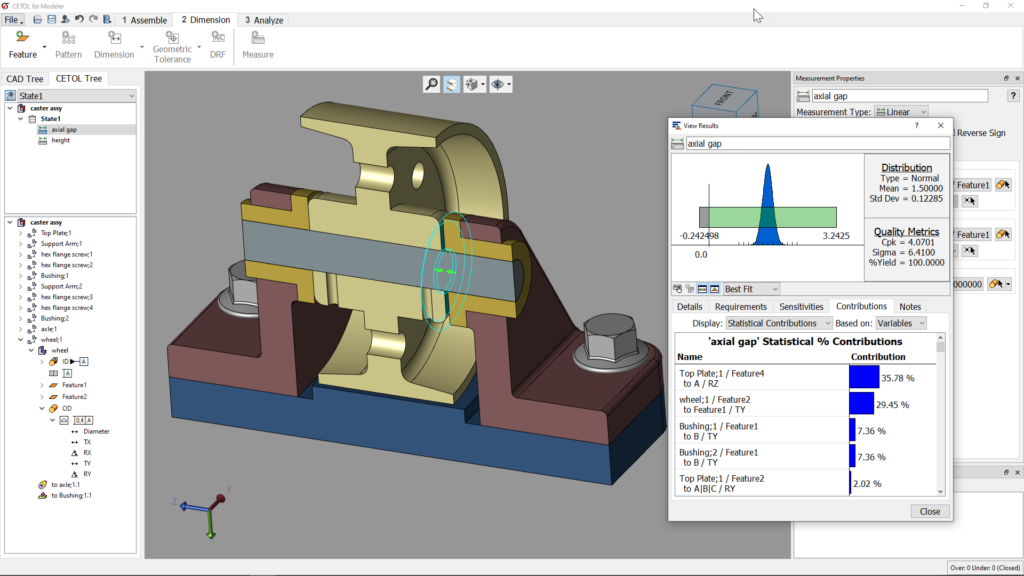

Tolerances limit the variation allowed for individual feature geometry, such as form and size, and they limit the geometric relationship between features, such as orientation and location. Tolerance Analysis and Tolerance Stackups are the tools and techniques used to understand the cumulative effects of variation (from tolerances and other variables), and to ensure these cumulative effects are acceptable.

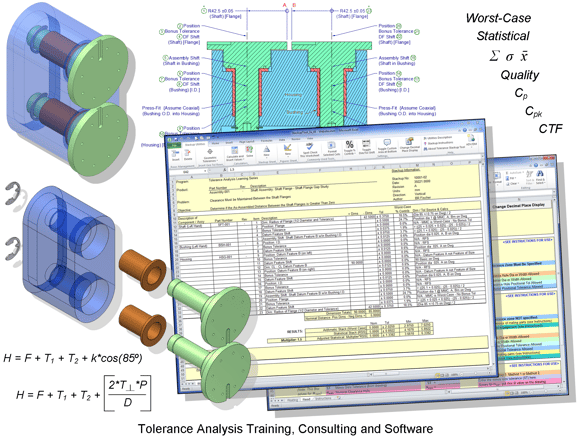

There are two methods used to specify tolerances: traditional Plus and Minus Dimensioning and Tolerancing and Geometric Dimension and Tolerancing (GD&T). In addition, ASME Y14.5 dimensioning and tolerancing and ISO dimensioning and tolerancing allow the use of tolerance codes based on the ISO system of limits and fit, found in ASME B4.2 and ASME B4.3 and ISO 286-1 and ISO 286-2. The point of Tolerance Analysis is ultimately to prove that design geometry, the specified Dimensioning and Tolerancing values, and the Dimensioning and Tolerancing scheme will work. Note that the only way to precisely specify the geometric requirements is through the use of GD&T. Although Plus and Minus Dimensioning and Tolerancing is still commonly used, and we explain how best to perform Tolerance Stackups on parts and assemblies based on Plus and Minus Dimensioning and Tolerancing, part of our goal is to help our clients understand why GD&T is a much better system for their business.

Tolerancing, Tolerance Analysis and Tolerance Stackups have been around in one form or another for a long time. Sometime in the past, it became necessary to determine whether mating parts would fit together before they were manufactured. A design team may have needed to know how thin a part feature could become during manufacture, to make sure the part would remain strong enough to work. They may have needed to know how large a hole could be and how far it could be from its nominal position to make sure there was enough surface contact to properly distribute the load from a fastener. It may have been important to know that all the parts would be interchangeable. Perhaps the manufacturing team needed to understand why the parts in an assembly that met the drawing specifications did not fit together at assembly. By performing Tolerance Analysis and Tolerance Stackups, these and many other important questions about the design can be answered. Indeed that is why Tolerance Analysis and Tolerance Stackups are done – to provide answers to questions. Tolerance Analysis and Tolerance Stackups will help you to understand and solve your tolerancing problems.

How can the designer determine if parts will fit together at assembly? Better yet, how can the designer determine if imperfect parts will fit together at assembly, as all parts are imperfect? How much imperfection or variation is allowable? Does it matter if a part is manufactured a bit larger than nominal, and the mating part is manufactured smaller than nominal? What if both parts are manufactured on the small side, but mating holes in each part are slightly tilted or out of position? What affects the performance of the assembly more – variation in size or variation in position? What happens to a feature on one part if a surface on the mating part is tilted? These questions all lead to a Tolerance Stackup.

Tolerance Analysis is part art and part science. All Tolerance Analyses and Tolerance Stackups are truly three-dimensional; the problem solver is forced to frame the problem in such a manner as to facilitate a one-dimensional solution. Simplification and idealization of the problem is required.

The importance of a standardized approach to solving Tolerance Analysis problems cannot be overstated. Equally important is the need to communicate the results of a Tolerance Stackup. Rarely, if ever, is a Tolerance Stackup done without the need to share the results or to convince someone else to make a change. Techniques must be used that help ensure that the problem will be solved correctly and that the results will be understood by all parties involved. Our training and material addresses these needs and presents the techniques for developing and formatting a standardized Tolerance Stackup Report.

As stated above, Tolerance Analysis is an art, and it requires practice to become an effective problem solver. Using our techniques, our clients will be on the path to understanding and effectively solving their tolerancing problems.

We strongly suggest you consider our GD&T training and tolerance analysis training courses to help you understand your variation, how to quantify it, and how to mitigate its effects in your products.