Shanghai Koito Automotive Lamp Co. Ltd. improves design with Sigmetrix

One of China’s largest passenger Vehicle lighting manufacturers selects CETOL 6 Sigma for Tolerance Analysis Solution

McKinney, TX – January 13, 2015 – Shanghai Koito Automotive Lamp Co., Ltd., a company that has more than a 40% share in China’s passenger Vehicle lighting market, has selected Sigmetrix CETOL 6 Sigma tolerance analysis solution as an integral part of its quality production and design robustness initiative. This program is committed to meeting the requirements of their customers.

passenger Vehicle lighting market, has selected Sigmetrix CETOL 6 Sigma tolerance analysis solution as an integral part of its quality production and design robustness initiative. This program is committed to meeting the requirements of their customers.

Shanghai Koito Automotive Lamp Co., Ltd. chose CETOL 6σ and also entrusted the 3D tolerance analysis team of Cybernet China to work on a few projects. After several tolerance analysis projects were completed they could see the results from CETOL 6σ were accurate and verified the resulting data in practice.

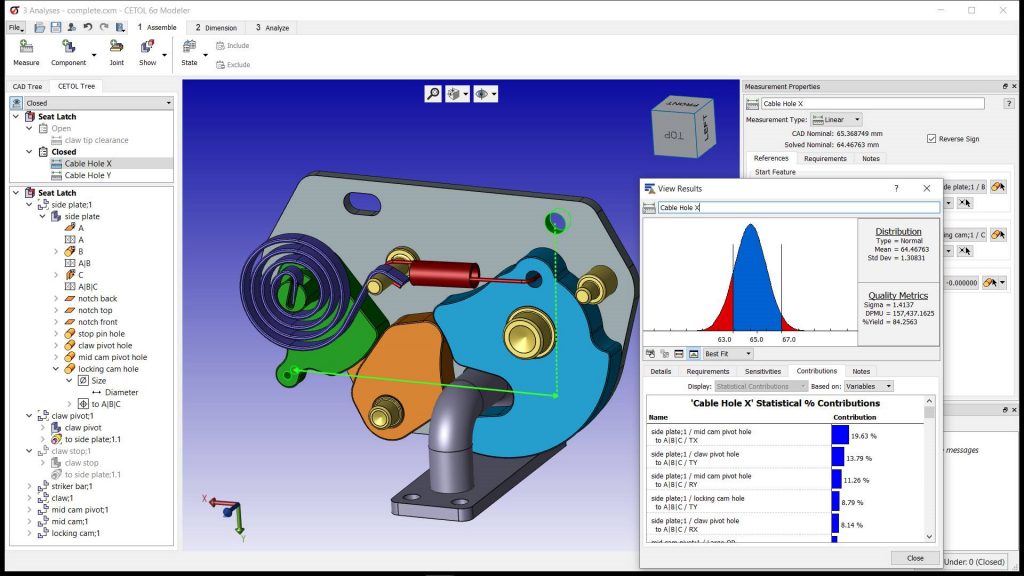

Sigmetrix, LLC developed the seamless CAD integrated software CETOL 6σ which helps the product design engineers at Shanghai Koito to improve and manage the quality level of the lamp assemblies with efficiency. “CETOL 6σ can be seamlessly integrated with CATIA and simulate the real world assembly environment. For assemblies of automobile lamps, the effect of RPS errors, welding deviations and manufacturing variations can be considered. A 3D tolerance analysis of gaps and surface differences in automobile lamps can help attain design robustness and improve production quality,” said Product Design Department Manager Qi Fan.

“We are delighted that Shanghai Koito is integrating CETOL 6 Sigma into their CATIA platform, and we’re confident that their product design engineers will achieve the design robustness and quality improvements they are looking for,” remarked Sigmetrix President Chris Wilkes. “We are pleased that our continued commitment to invest in the China market has contributed to the success of our tolerance analysis and GD&T products and proud to be a partner with Cybernet China.”

Learn more about CETOL 6σ at https://www.sigmetrix.com/products/cetol-tolerance-analysis-software/.

About Sigmetrix, LLC

Sigmetrix is a global provider of comprehensive, easy-to-use software solutions that help users achieve robust designs through tolerance analysis and the correct application of GD&T. With over 20 years of research and development, Sigmetrix products eliminate the error between as designed assemblies and as produced products. For more information, visit their website at www.sigmetrix.com.

About Shanghai Koito Automotive Lamp Co. Ltd

Shanghai Koito Automotive Lamp Co. Ltd., a Sino-Japanese joint venture, was established on February 28th, 1989. It is an innovative enterprise in Shanghai. Skoito is specialized in producing automotive lamps, which cover more than 500 varieties such as Buick, Excel, GL8, Sail, Passat(B5), STNseries, Audi, Jetta, Changan-Suzuki; Chongqing-Qingling, Nanjing-Iveco, Zhengzhou-Nissan, Jiangxi-Isuzu; Zhuzhou-Yamaha, Jinan-Qingqi, Tianjing-Honda, Jincheng-Suzuki, Shanghai-Happiness, Guangdong-Changjiang, Tianjing-Subaru, North-E-Cho. Besides, there are over 40 kinds of products exported to international market, e.g. US, European market,Japan, etc. For information, visit website at www.skoito.com.

.jpg)