Unlock More Efficient, Collaborative, and Error-Resistant Processes

A Unified 3D Model for Streamlined Collaboration, Reduced Errors, & Enhanced Efficiency

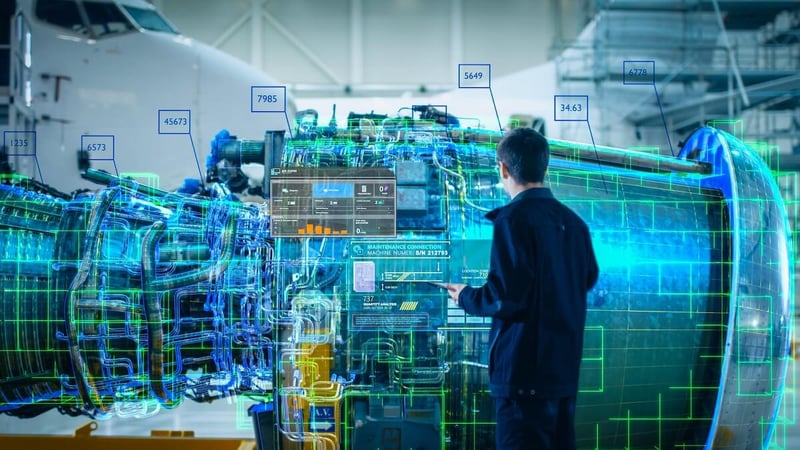

Model-based definition (MBD) is an approach to product development that supplements traditional 2D drawings with a comprehensive 3D digital model, containing all necessary design and manufacturing information such as dimensions, tolerances, annotations, and other specifications. MBD focuses on deploying a singular, authoritative source of information in a digital format, containing all necessary product specifications, dimensions, tolerances, and other relevant details within the “digital twin.”

Without MBD systems in place, organizations may experience inefficiencies, increased risk of errors, and difficulties in adapting to the demands of Industry 4.0 practices.

Discover the Benefits of Model-Based Definition

Adopting model-based definition leads to more efficient, collaborative product development and manufacturing workflows, ultimately contributing to improved product quality and efficiencies.

Enhancing the Utilization and ROI of Your MBD Investments

Unlock Precision and Performance in Model-Based Definition

Aligning with GD&T, GPS, and Industry Standards for Enhanced Model-Based Definition

Our solutions ensure that MBD data is not only accurate but also highly usable across the entire product development process.

-

Ensure the geometric and dimensional controls specified by GD&T and GPS standards are correctly implemented within the digital models used in MBD.

-

Assist in translating and integrating GD&T and GPS specifications into MBD models, maintaining accuracy and compliance throughout the design and engineering process.

-

Perform automated checks to verify that all necessary geometric and dimensional controls have been appropriately defined and consistent with the given requirements.

-

Minimize potential ambiguities that could arise during the design, manufacturing, or inspection processes by clearly defining the GD&T and GPS definitions within the MBD models.

-

Allow for explicit and detailed specification of geometric and dimensional controls to define tolerances, constraints, and specifications to reduce conflicting interpretations.

-

Define PMI data, including geometric dimensioning, tolerancing, annotations, and other manufacturing information directly within the 3D models used in MBD.

-

Validate PMI is accurately defined and compliant with the intended design and manufacturing requirements.

-

Ensure manufacturing instructions and annotations are readily available within the MBD framework for seamless communication throughout the product lifecycle.

-

Cross-reference and verify semantic associations within the model, ensuring that the relationships between various design parameters are accurate and logical.

-

Confirm semantic principles are applied effectively within MBD to ensure that the digital models maintain meaningful and accurate representations of design information.

The Sigmetrix Software and Training Suite

Our solutions and training help teams improve product quality, optimize dimensioning schemes, and increase usability of MBD investments.

-

Help engineers understand and manage the impact of dimensional and geometric variations in design using CETOL 6σ, a comprehensive, 3D model-based tolerance analysis solution.

-

Ensure GD&T and GPS specifications are accurately represented and analyzed in the digital model, providing a standardized language for defining and communicating tolerances.

-

Push towards 3D models to serve as the authoritative source of information for the product, an important piece of a model-based enterprise (MBE).

-

Allow teams to share and analyze tolerance data, ensuring that everyone involved in the product development process has access to accurate and up-to-date information.

-

Learn the pros and cons, techniques, and best practices in both 3D MBE and MBD with focused training.

-

For a broader approach to improving your business’s mechanical variation management, utilize our consulting services. You can also choose to focus on project-based or software installation consulting.

Simplifying Tolerance Analysis Across the Enterprise for Better Products

Discover how Sigmetrix can help you save time, improve profitability, innovate more, and maximize return on your investments across the enterprise.

Here’s How Companies Like Yours Use Sigmetrix to Maximize Their MBD Investments

These companies implemented Sigmetrix’s tolerance analysis and GD&T solutions to ensure accurate and optimized 3D models for enhanced MBD implementation and product quality.

Discover the improvements these organizations experienced with Sigmetrix.