Sigmetrix Enters Autodesk User Community with EZtol Autodesk Inventor

Sigmetrix broadens its precise, easy-to-use mechanical variation and tolerance analysis software product portfolio with its new 1D analysis tool for Autodesk Inventor

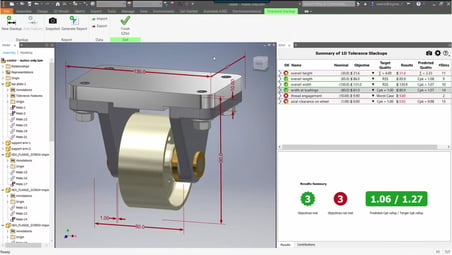

MCKINNEY, Texas – October 3, 2017 – Sigmetrix, global experts in GD&T and mechanical variation, announced their newest software release for Autodesk Inventor users – EZtol for Autodesk Inventor. This 1D analysis tool is designed to enable designers and engineers to quickly understand the impact of part and assembly variation on the fit and performance of their products.

EZtol for Autodesk Inventor builds on the capabilities of Sigmetrix’ standalone EZtol solution by utilizing tolerance information (i.e. PMI) from the dimensions in the part files. This new version also includes auto-part-loop generation; EZtol will create the loops based on assembly constraints or joints, the user will simply select the loop and the analysis will be calculated! With the utilization of PMI and assembly constraint and joint information it has some of the most powerful automation capabilities of any product in the Sigmetrix portfolio.

“We are thrilled to be able to expand into the Autodesk user community with EZtol for Autodesk Inventor,” stated Chris Wilkes, President and CEO of Sigmetrix. “We are recognized as experts globally for providing tolerance analysis and GD&T software solutions, as well as industry-leading training and consulting services, and now we are proud to offer tolerance analysis solutions in all major CAD markets.”

EZtol for Autodesk Inventor is an add-in for Inventor 2018 that has been designed to make it easier to create, manage and report upon multiple 1D tolerance analyses in an assembly. Some of the additional features you’ll get with EZtol for Autodesk Inventor are:

- Builds the analysis on top of the 3D design model:

- Uses the actual nominal distances between surfaces/features from the design.

- Helps to ensure all components in the loop are included.

- Shows the optimum dimensioning scheme for the single analysis.

- Automatically calculates the worst-case, RSS, and statistical results of the analysis. Metrics for statistical results can be reported as: Cpk, Sigma, DPMO, or % Yield.

- Lists of contributors sorted from largest to smallest.

- Define multiple tolerance stackup analyses on the same model.

- Provides a summary table showing the objectives and results of each stackup analysis along with a visual indication of whether the requirement has been met.

- Automatically finds stackup loop of parts between stackup endpoints from Inventor assembly constraints and joints.

- Links to tolerances, both on linear dimensions and geometric (i.e. GD&T & GPS), so that changes update both the design and analysis data.

- Stores the dimensions, with tolerances, defined for each part so that the user doesn’t have to re-enter them for each loop. This also allows the automatic updating of all analyses when the user makes a modification to a tolerance used in multiple analyses.

- Generates detailed report with graphical view of the dimension loop over the models involved and a graphical presentation of results and the top contributors.

- Provides an indication that the tolerance stackup may not be 1D in nature including a note that the results provided may underestimate the actual variation that will occur during production.

Sigmetrix is pleased to be exhibiting and demonstrating this solution that can leverage the new MBD capabilities of Autodesk Inventor at Autodesk University to be held November 13 – 16, 2017 in Las Vegas, NV. Peter De Strijker will be presenting “Inventor 2018 Model-Based Definition: Why and How to Apply” which will include a focus on downstream consumption of MBD and a short demonstration of the functionality of EZtol for Autodesk Inventor by Stephen Werst, Senior Product Strategist at Sigmetrix. Learn more about the conference at: http://au.autodesk.com/las-vegas/overview.

“We were excited to partner with Autodesk to embed our GD&T Advisor technology into Autodesk Inventor 2018 to augment its MBD capabilities,” commented Stephen Werst, Senior Product Strategist at Sigmetrix. “But getting the correct tolerances, whether expressed as G&DT or +/- tolerances, requires a tolerance stackup analysis to see how those tolerances impact the assembly requirements. EZtol for Autodesk Inventor bridges the gap between manual tolerance stackups and an advanced tool like CETOL 6σ perfectly.”