What is Model Based Definition?

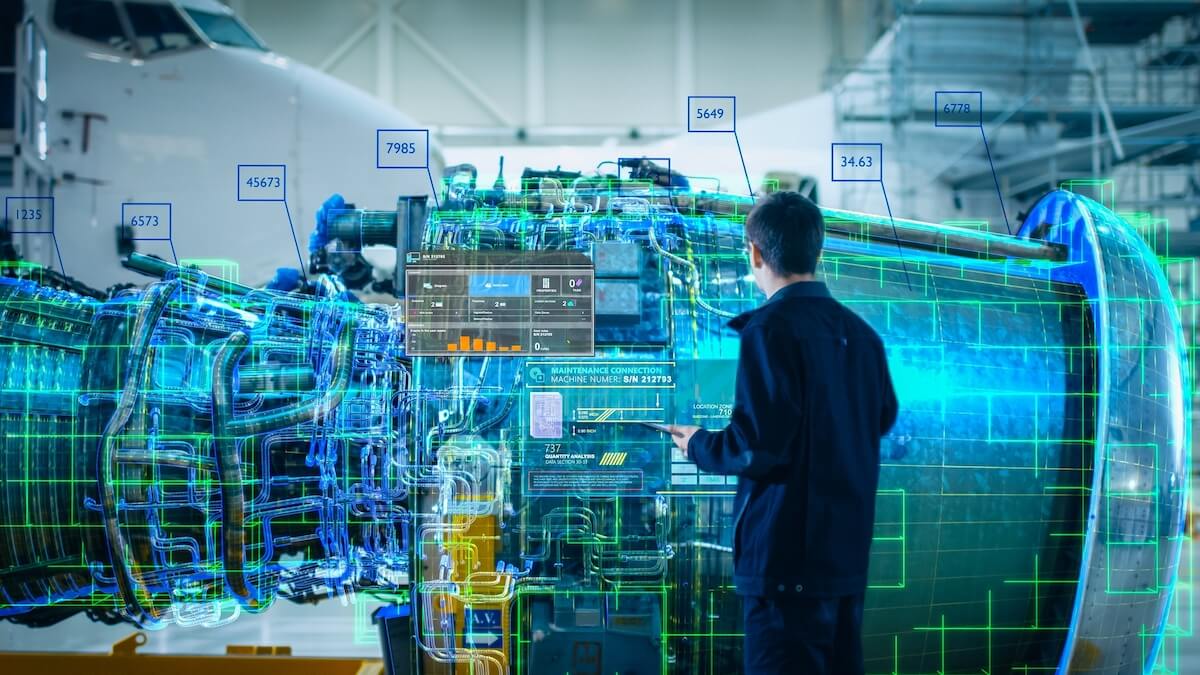

What is a model?

Model = Geometry + Attributes + Annotations

Why Should Model Based Definition be Used?

In short, it is better, faster, and cheaper!

- US Defense Logistics Agency (DLA) estimates that moving to Model Based Definition Data Packages will reduce procurement costs by 27%. This same survey estimated that almost 19% of scrap and rework costs were attributable to poor quality of the design specification

- US Dept of Defense estimates that 60% of the supplier data received has errors between models and drawings despite the fact that 30% of the total product development budget was spent on creating and maintaining drawings

- Many manufacturing systems can utilize information directly from the 3D models without having to be explicitly programmed

- 3D Printing for prototyping

- CAM Software for machining the parts

- Inspection software

- Complete 3D models can feed directly into engineering analysis programs to verify the performance of the design