Include Effects of Thermal Expansion in your Model with CETOL 6σ v11.2

CETOL 6σ v11.2 tolerance analysis software adds thermal expansion, improves feature collector, & floating joint tools

MCKINNEY, Texas – April 21, 2022 – Sigmetrix, experts in mechanical variation management, announced their latest version of CETOL 6σ tolerance analysis software, version 11.2, is now available for immediate download.

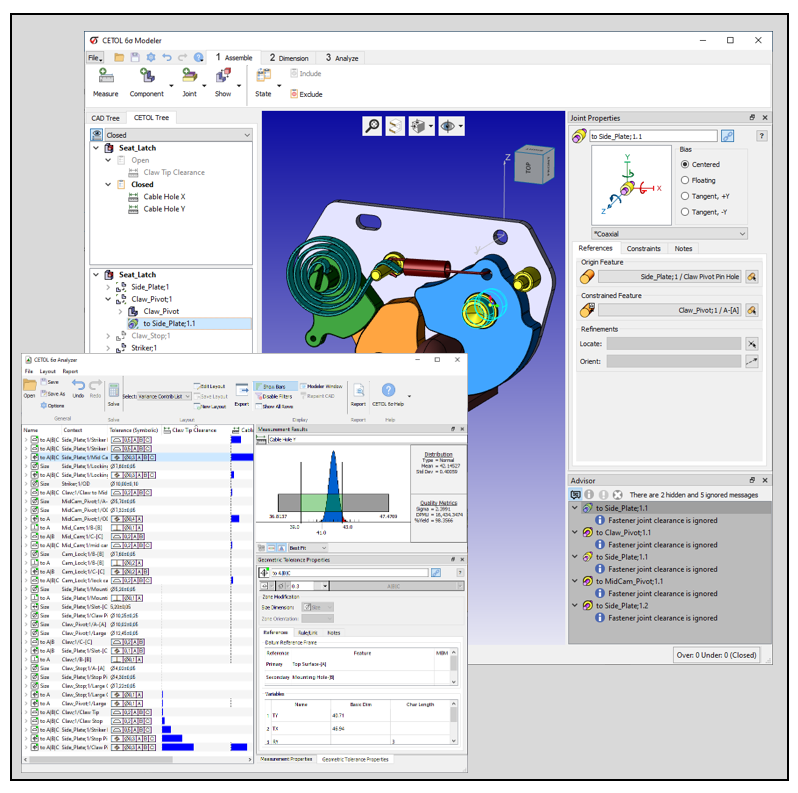

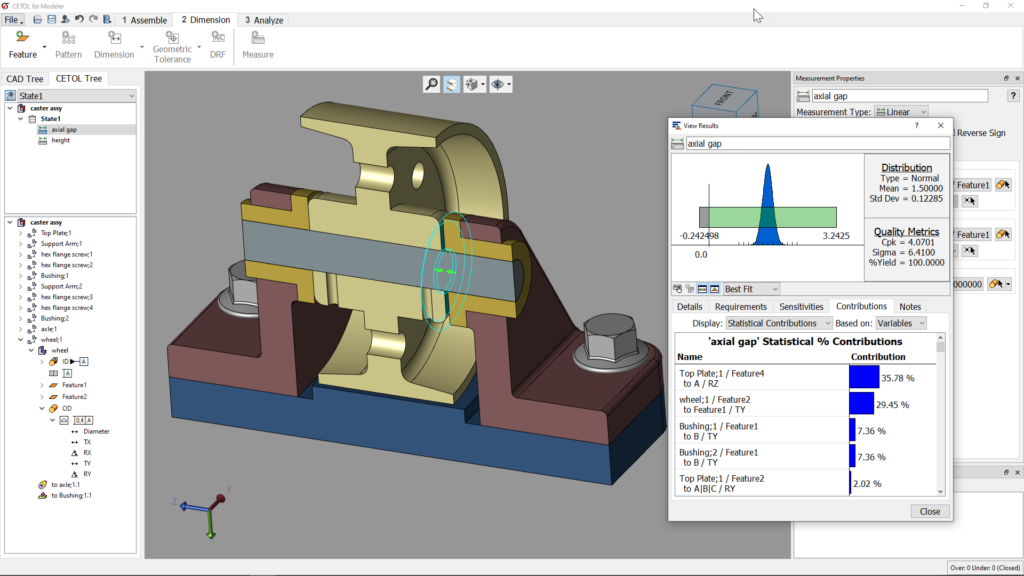

CETOL 6σ is the world’s most powerful tolerance analysis software and was specifically developed to promote manufacturing efficiency and productivity. Designers and engineers use CETOL 6σ to see the impact that tolerance changes will have on their overall assembly. The cutting-edge technology enables product development teams to optimize their design and manufacturing goals so they can deliver higher quality and more precisely engineered products.

Tolerance analysis benefits businesses in many ways. It allows companies to gain confidence in their product and process decisions before making costly investments. It can also help improve profitability by balancing quality with manufacturing cost. Companies can also realize a faster time to market by reducing the need for additional design and prototype cycles.

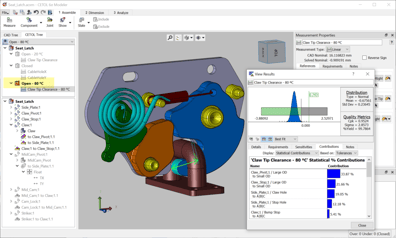

This new version of CETOL 6σ builds upon the powerful features already in place and adds a great deal of usability and modernization. New features of CETOL 6σ v11.2 include:

- Thermal Expansion

- Assembly state properties include a Thermal tab where you can indicate the temperature at which to evaluate the assembly.

- Part and Assembly properties include a Thermal tab where you can specify the coefficient of thermal expansion.

- Feature Collector improvements

- Shows the parent part information for the selected geometry.

- Continuous Add Feature mode.

- Message indicating what to select.

- Floating joint improvements

- A single constraint representing float and improved presentation of the float constraint properties that shows the joint reference features and their tolerance properties.

- More accurate worst-case analysis for floating joints (i.e., circular, rather than square, worst-case zone for float between a pin and a hole).

- Separate contributions for float are shown for feature variation and joint clearance.

- Save files to specified folder

- When you select the option to save the CETOL data to separate files, you have the option to save the files to a specified folder (rather than to the same folder as the where the CAD files are stored). This option is especially important when the CAD files are in a PLM workspace rather than on a local disk drive.

- Improved layout control and performance in Analyzer

- The controls for managing layouts in the Analyzer window and the performance of the layout updates have been improved.

“This latest version of CETOL 6σ is another tremendous advancement in the overall user experience with its ability to take into account the effects of thermal expansion,” said Sigmetrix President and CEO, James Stoddard. “We strive to improve each release of CETOL 6σ with features and functionality to add functionality that our customers need to design better products through mechanical variation management.”

Sigmetrix provides a complete portfolio helping customers design and produce better products through mechanical variation management. In addition to CETOL 6σ, Sigmetrix offers an array of software and training solutions including:

- EZtol, a 1D analysis tool that works directly with your CAD models, including embedded tolerances (PMI), to make it easier to create, manage, and report upon multiple 1D tolerance analyses, or stackups, in an assembly

- GD&T Advisor, an interactive tool that provides expert guidance on the correct application of GD&T withing the PTC Creo environment

- Training on a variety of topics including GD&T, tolerance analysis, dimensional management, and MBD / MBE

- Computer-Based Training on either an individual or enterprise basis developed to make learning at your own pace easy and intuitive.

- Consulting and implementation services team with years of experience in tolerance analysis and GD&T definition offers a variety of consulting services to augment your team, speed your project along and run analyses for your assemblies

CETOL 6σ v11.2 is available immediately for current users at: https://sigmetrix.flexnetoperations.com

For more details on the capabilities of CETOL 6σ, visit https://www.sigmetrix.com/products/cetol-tolerance-analysis-software.

Sigmetrix will be hosting a webinar to show attendees the new features and functionality of CETOL v11.2. The webinar will be held on Thursday, May 5, and anyone interested in attending can register at https://us06web.zoom.us/webinar/register/WN_tweqnbt8QnyDfpLfgexo5Q.

About Sigmetrix

Sigmetrix has been helping companies produce better products for over 20 years through a combination of software solutions, training, and consulting services that focus on managing the impact of mechanical variation. For more information, visit their website at www.sigmetrix.com.