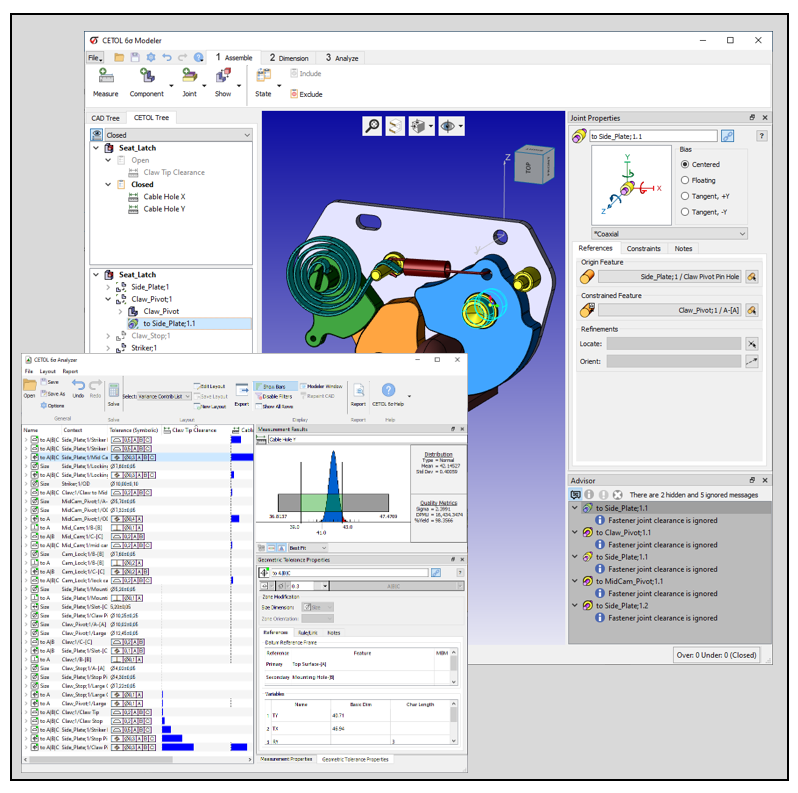

Sigmetrix CETOL 6σ v11.1 3D Tolerance Analysis Software Now Available

CETOL 6σ v11.1 tolerance analysis software improves profile tolerances, section views, and patterns

MCKINNEY, Texas – November 2, 2021 – Sigmetrix, experts in mechanical variation management, announced their latest version of CETOL 6σ tolerance analysis software, version 11.1, is now available for immediate download.

Tolerance analysis benefits businesses in many ways. It helps improve profitability by balancing quality with manufacturing cost. Companies can also realize faster time to market by reducing the need for additional design and prototype cycles. Finally, it allows companies to gain confidence in their product and process decisions before making costly investments.

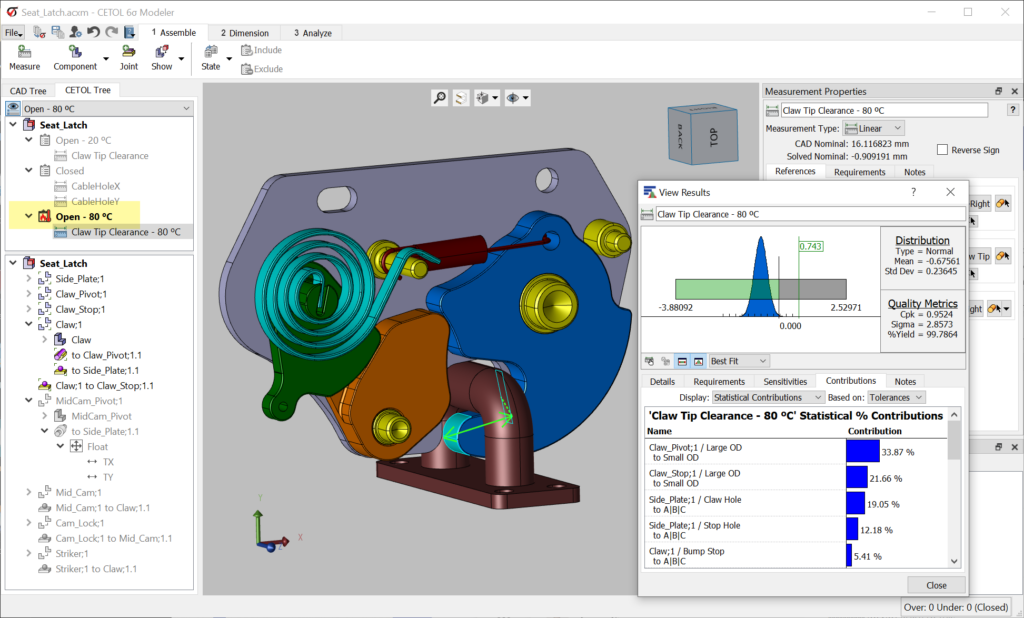

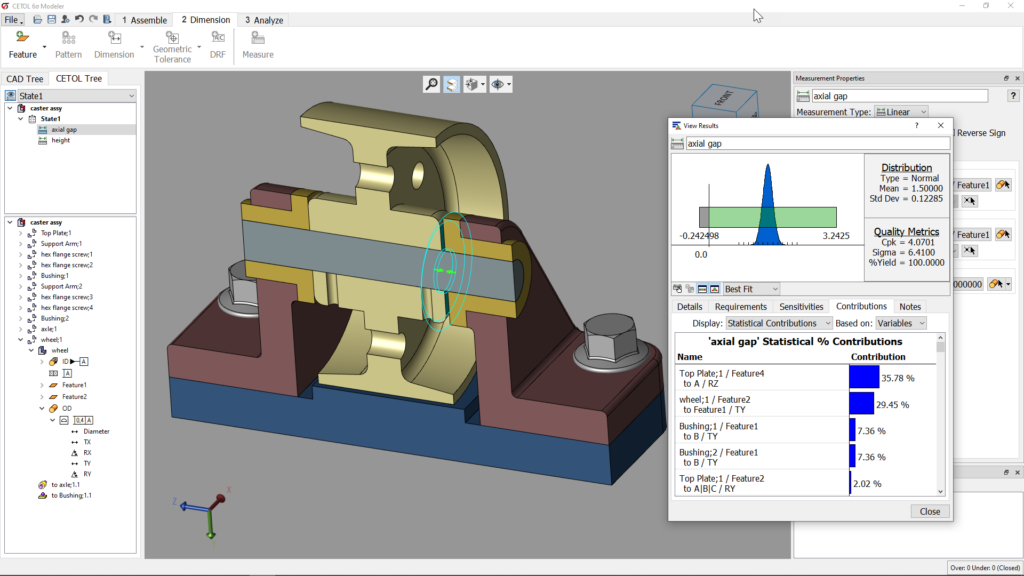

CETOL 6σ enables product development teams to easily and fully understand the often-complex impact of dimensional and assembly variation on their designs. This knowledge enables them to make adjustments before problems appear in manufacturing or, even worse, in their customers’ hands. Users of all expertise levels will appreciate the multiple levels of assistance available within the software. This new version of CETOL 6σ builds upon the powerful features already in place and adds many improvements, including:

- Profile geometric tolerance now controls size as well as location and orientation variables when applied to features of size – When applied to features of size, specifically cylinders, cones, spheres, torus, and arc feature types, profile tolerance types now control the variation in all applicable variables. In addition to and improved, easier workflow requiring no manual changes that might break the connection to the Product Manufacturing Information (PMI), CETOL 6σ v11.1 now helps the engineer understand which of the variables that are controlled by the Profile tolerance influence the design objectives most significantly in both worst-case and statistical analyses. The Variation Rule controlling the allocation of the tolerance zone to each of the variables for statistical analyses has also been updated.

- Isolate CAD display on active object in PTC Creo and SOLIDWORKS – Previous versions of CETOL 6σ for CATIA and NX had a feature that would isolate a component in the tree, such as an individual part, when the user selected it as the active object in CETOL 6σ. This convenience enables the user to focus on the specific CAD object, automatically hiding the rest, for tasks like defining dimensions and tolerances, rather than having to open the part in a separate session. CETOL 6σ v11.1 extends this functionality to the Creo and SOLIDWORKS versions as well.

- Section views for NX and CATIA – One of our most requested enhancements by CATIA and NX users, CETOL 6σ 11.1 now supports the definition of sectional views of the CAD model rather than having to generate them in the source CAD models. Sectional views can also be saved within the CETOL 6σ data structure.

- Continued Enhancements to Patterns – The previous version of CETOL 6σ, v11.0, was the first to support patterns of features. CETOL 6σ v11.1 extends the capabilities in several key areas:

- Multiple coaxial cylinders may now be defined as a pattern in addition to multiple cylinders with parallel axes that was included in the previous release.

- Topological constraints between arc features to specific to pattern members are now supported.

- Many common pattern operations are now available in the model tree context menu.

- Individual pattern members may now be designated as a datum feature.

“With this latest release of CETOL 6s we continue to provide enhancements that focus on the overall user experience,” said Sigmetrix President and CEO, James Stoddard. “Our vision is to help companies make better products through mechanical variation management and we strive to make this potentially complex topic as accessible as possible.”

Sigmetrix provides a complete portfolio helping customers design and produce better products through mechanical variation management. In addition to CETOL 6σ, Sigmetrix offers an array of software and training solutions including:

- EZtol, a 1D analysis tool that works directly with your CAD models, including embedded tolerances (PMI), to make it easier to create, manage, and report upon multiple 1D tolerance analyses, or stackups, in an assembly

- GD&T Advisor, an interactive tool that provides expert guidance on the correct application of GD&T withing the PTC Creo environment

- Training on a variety of topics including GD&T, tolerance analysis, dimensional management, and MBD / MBE

- Computer-Based Training on either an individual or enterprise basis developed to make learning at your own pace easy and intuitive.

- Consulting and implementation services team with years of experience in tolerance analysis and GD&T definition offers a variety of consulting services to augment your team, speed your project along and run analyses for your assemblies

CETOL 6σ v11.1 is available immediately for current users at: https://sigmetrix.flexnetoperations.com

For more details on the capabilities of CETOL 6σ, visit https://www.sigmetrix.com/software/cetol.

If you’d like to see a short demo of the newest version of CETOL in action, be sure to attend our upcoming webinar scheduled on November 12, 2021. Register at https://us06web.zoom.us/webinar/register/WN_ULyeQOVOTh-r9zlicj0LNw

About Sigmetrix

Sigmetrix has been helping companies produce better products for over 20 years through a combination of software solutions, training, and consulting services that focus on managing the impact of mechanical variation. For more information, visit their website at www.sigmetrix.com.